Protecting Your Hands: A Guide to Your Most Essential Tools

Understanding Risks to Your Hands

Your hands are the most versatile and valuable tools you bring to the job every day, particularly in the demanding field of sanitation. However, their complexity also makes them highly vulnerable to injury if not properly protected. At Augment, safety is our core priority, which is why we provide specialized training to help you understand the "anatomy of risk" associated with your hands. By staying alert and following established best practices, you can navigate the physical demands of the job while ensuring you return home with your health and dexterity intact.

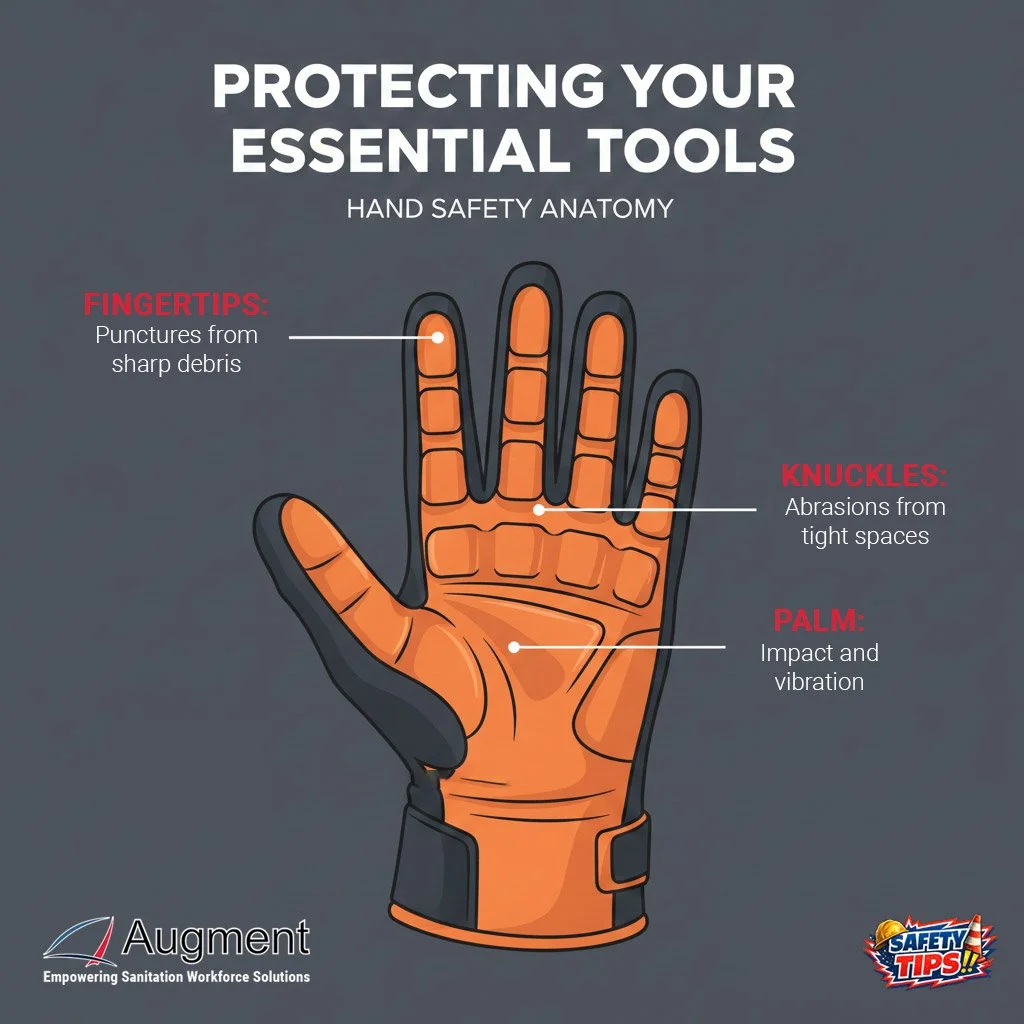

Understanding the specific hazards of sanitation work is the first step toward prevention. As shown in our safety anatomy guide below, different parts of the hand face unique threats: fingertips are constantly at risk of punctures from sharp debris like glass or metal hidden in waste; knuckles are prone to painful abrasions when working in the tight, jagged spaces of truck hoppers or bins; and the palms bear the brunt of repetitive impact and heavy vibrations from machinery. Beyond these areas, "pinch points" - those dangerous zones where hands can be caught between moving parts or heavy lids - are a constant threat. Training at Augment focuses on maintaining a "buffer zone" of awareness, teaching you to visualize these danger zones before you reach into a workspace or engage a mechanical lever.

Bonus hand safety tips BEFORE you put your gloves on

Check for thinning/holes.

Test the grip surface.

Ensure a snug, non-slipping fit.

Understanding How to Combat Risk

To combat these risks, Augment enforces a strict PPE policy that centers on our high-performance, company-issued safety gloves. These aren’t standard work gloves; they are engineered with reinforced padding for the palms to dampen vibration, textured grips for the fingertips to prevent slips, and durable shielding for the knuckles. However, even the best gear can fail if it is worn out. We train every worker to perform a "pre-shift inspection," looking for thinning material, compromised seams, or chemical degradation. Remember: if your gloves are compromised, your hands are too. Always ensure a snug fit, as loose material can actually become a hazard by getting caught in moving machinery.

Ultimately, hand safety is a shared responsibility and a proactive discipline. Beyond just wearing your gloves, we encourage "hands-off" techniques whenever possible—using tools, hooks, or brooms to clear debris rather than reaching in with your fingers. By combining Augment’s specialized gear with a high level of situational awareness, we create a culture where every worker is empowered to protect their livelihood. Stay vigilant, respect the power of the machinery you operate, and always keep your "essential tools" guarded by following our proven safety protocols.